Poly Plastic Products, a pioneer in blown film extrusion, manufactures polyethylene bags to your specifications employing all forms of prime resins and superior equipment. Our up to date, in-house test laboratory, well trained production personnel, and quality control procedures will ensure your continued satisfaction.

Poly bags are used as bin liners, box liners, drum liners, FDA food bags, furniture covers, gaylord liners, mattress covers, medical and surgical bags, and pallet covers.

PPP 100 Series - 100% Butene LLDPE

PPP 200 Series - 100% Hexene LLDPE

PPP 300 Series - 100% Super Hexene LLDPE

PPP 400 Series - High Clarity Proprietary Blend

PPP 500 Series - A four component blend with enhanced physical properties to meet strength requirements of down gauging (a value add product).

Additives

EVA

UVI

Slip

Anti-stat

Scented

Flame Retardant

Anti-Block

Rust Inhibitor

Degradable

Size Range

LLDPE

Lay Flat Bags - 12" to 97"

Gusseted Bags - 6" x 3" x 12" to 80" x 55" x 250"

Sheeting - "12 x "240 (Center Folded) 8" x 117" (Lay Flat)

High Density

17" x 18" to 43" x 48" - stock sizes

(Star bottom/perforated on coreless rolls)

Custom run to your specifications on LLDPE & HDPE

Color

Standard Tints

Standard Opaques

Specialty Colors

Gauge Range

LLDPE - .0005 to .007 mils

HDPE - 6 to 23 microns

Printing (LLDPE ONLY)

Random Repeat - 1 color/2 sides

Registered 2 color/1 side

All color concentrates are FDA approved and are heavy metal free.

All prime resins are FDA approved.

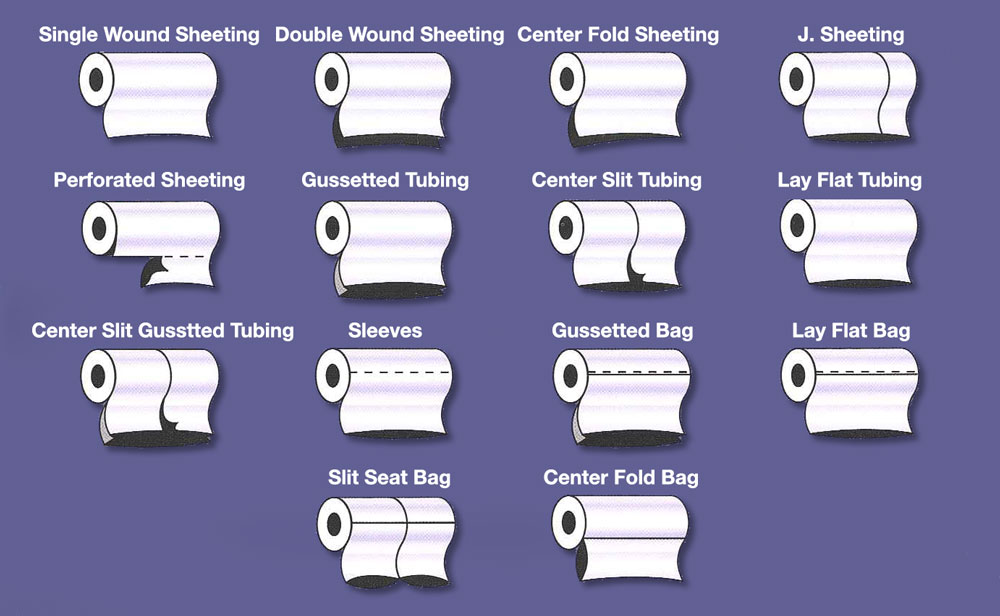

Product Configuration